Ultrasonic flow meters have many applications thanks to their non-intrusive design and measurement capabilities. Here are some common industries where ultrasonic flow meters are used and instructions on how to implement them properly.

Typical Application Industries

Some key industries that frequently use ultrasonic flow meters include:

Water and Wastewater: Measuring clean water, wastewater, and slurries for utilities, treatment plants, and mining operations.

Chemical: Monitoring process flows in chemical manufacturing, mixing, and batching applications.

Oil and Gas: Custody transfer metering of petroleum products in pipelines and at tank farms.

Power: Flow measurement in power plant cooling water, feedwater, and pumped storage systems.

Pulp and Paper: Managing flows within papermaking, pulp processing, and biomass handling.

Food and Beverage: Measuring liquid ingredients, mixtures, and final products throughout production.

How to Use Ultrasonic Flow Meters

Here are the basic steps to implement ultrasonic flow measurement:

1. Size the Application: Determine pipe dimensions, fluid properties, flow rates, and accuracy needs.

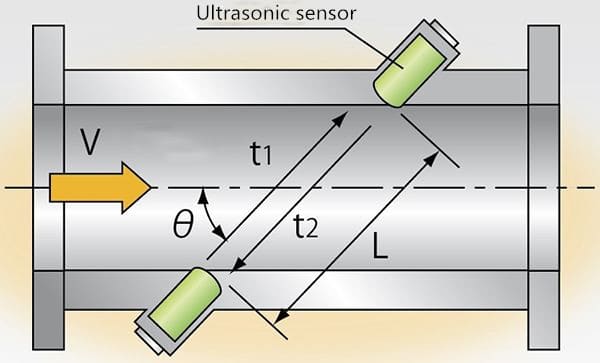

2. Select the Meter: Choose clamp-on or in-line style, number of paths, approvals, outputs based on sizing.

3. Install and Mount: For in-line mounting, follow piping guidelines. Clamp externally for a non-invasive installation.

4. Configure Settings: Enter pipe material and size, K-factor via the onboard digital interface or handheld.

5. Zero the Meter: Set flow to zero flow conditions for an initial calibration point if possible.

6. Commission and Verify: Check readings at known flow rates. Fine-tune settings if needed.

7. Monitor and Maintain: Record flow totals. Clean transducers periodically if externally mounted.

Considerations for Use

When using ultrasonic flow meters, pay attention to the following:

Pipe conditions - Surface roughness, deposits, valves can affect accuracy.

Flow profile - Disturbed flow profiles degrade performance; maintain straight runs.

Temperature - Compensate for temperature effects on sound velocity in fluid.

Gas content - Ultrasonic meters may not work well with high gas void fractions.

Pulsing flow - Accuracy reduces for intermittent, pulsing or very low steady flows.

ultrasonic flow meters have wide applications thanks to their versatility. Proper sizing, installation, configuration and process considerations ensure accurate long-term flow measurement.

Browse some featured ultrasonic flow meter models for your specific application needs.

Comments on “Applications and Use of Ultrasonic Flow Meters”